Project Description

2L/5L Vacuum Mixer

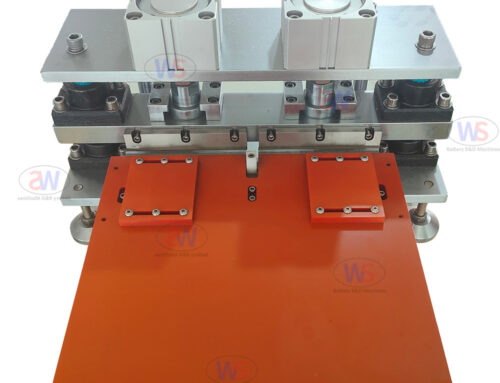

Dual shaft mixer & Disperser is a new model that combines the traditional mixer and high speed disperser. In response to the high solid content and high viscosity characteristics of the power battery slurry, an enhanced power mixer with higher speed and larger torque has been developed based on the original planetary power mixer.

2L Technical Parameters

| vacuum | -0.098MPa |

| structure type | single arm |

| Rotating speed | Revolution: 0 ~ 52r/min, rotation: 0 ~ 76r/min

(frequency conversion speed regulation); (frequency conversion speed regulation). |

| low speed shaft | Twist paddle (with scraper) |

| Linear Guides | Taiwan HIWIN |

| dispersion axis | Single high-speed shaft, two Φ40 dispersion discs on the shaft. |

| lifting method | Linear guide rail material cylinder electric lift, (0.37KW reducer) |

| lifting height | 180mm |

| temperature measurement method | The barrel wall PT100 sensor contacts the material |

| barrel positioning | The fixed block of the arc-shaped plate is used to lift and place, and the flange structure is set on the upper barrel to ensure the center positioning. |

| total power | 2.6kw+0.37KW reducer |

| power supply | AC: 3*380V, 50HZ |

| Dimensions | Length 1100 Width 660 Height 1300 (mm) |

| weight | about 450kg |

5L Technical Parameters

| structural style | Single arm type |

| speed r/min | Turn: 0 ~ 61 r/min, turn: 0 ~ 125 r/min (frequency conversion speed regulation);

High speed: 0 ~ 6800 r/min (variable frequency speed regulation). |

| low speed shaft | Mahua paddle |

| Scratch the wall shaft | 304 # material with 304 # scraper + PTeflon scraper |

| linear guide rail: | Taiwan HIWIN |

| Dispersed axis | Single high-speed axis, 2 sets of dispersed axis, two Φ 50 dispersed disks on each axis. Hardness HRC 63, linear speed up to 25m / s |

| Lift way | Electric lifting of linear rail material cylinder, (0.37KW reducer) |

| Lift height | 180mm |

| Temperature measurement mode | The bucket wall PT 100 sensor contacts the material |

| Bucket positioning | The arc plate is arranged, and the upper bucket is equipped with flange structure to ensure the central positioning. |

| aggregate capacity (KW) | 7kw |

| source | AC:3*380V、50HZ |

| outline dimension | Long 1250 W 770 H 1450 (mm) |

| weight (kg) | About 670kg |

| noise | Test noise from 1m distance of the outer wall of the equipment: 75dB |

| Solid content | 10%—72% |

| Applicable to slurry viscosity | 1000—40000mpa.s |

| Stir form | Compatible with dry process and wet process mixing process |

| Temperature display accuracy | 0.1℃ |

| seal components | NMP corrosion resistance |

| Overtemperature alarm function | The temperature can be set by itself |

| product percent of pass | 100% |

| equipment failure rate | 1% of the failure caused by the equipment |

| downtime | 30min / day (more than 30min fault once / month) |

| Equipment growth rate | ≥98% |

| function | With a vacuum device, with electronic scale, the positive and negative electrode is equipped with scraper fineness meter |

| Safety protection design | The mixing tank body has a safety protection design |

| control method | Siemens, PLC + Kunlun pass state, human-machine interface |

| cooling water | Equipped with chiller, cooling water inlet pneumatic ball valve, with flow switch. |

| temperature controlling system | Temperature range 0~80℃, cooling chiller 5℃, chiller flow 10L / min |

| Motor and electric box | Explosion-proof design |