Project Description

Small Battery Coating Machine for Laboratory and R&D Pilot-line

Coating (coated)

Operation function:

The slurry is continuously and uniformly coated on the surface of the conveying fluid, dried, and made into positive and negative electrode sheets respectively

- principle:

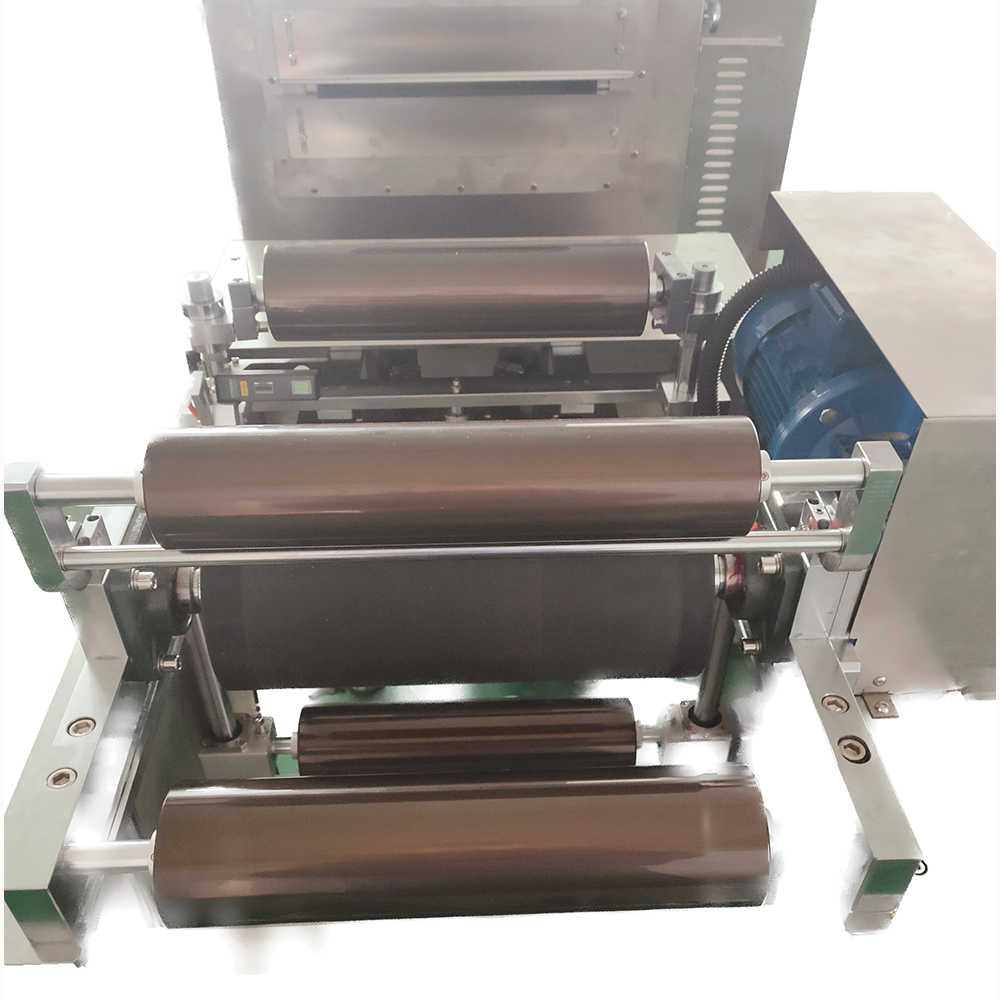

The coating roll rotation drives the slurry, adjust the slurry transfer amount by adjusting the scraper gap, and transfer the slurry to the substrate by using the rotation of the back roll or the coating roll, control the coating layer according to the thickness of the process requirements to meet the weight requirements, and remove the solvent in the slurry spread on the substrate by drying and heating, so that the solid material is well bonded to the substrate.

1. Equipment introduction

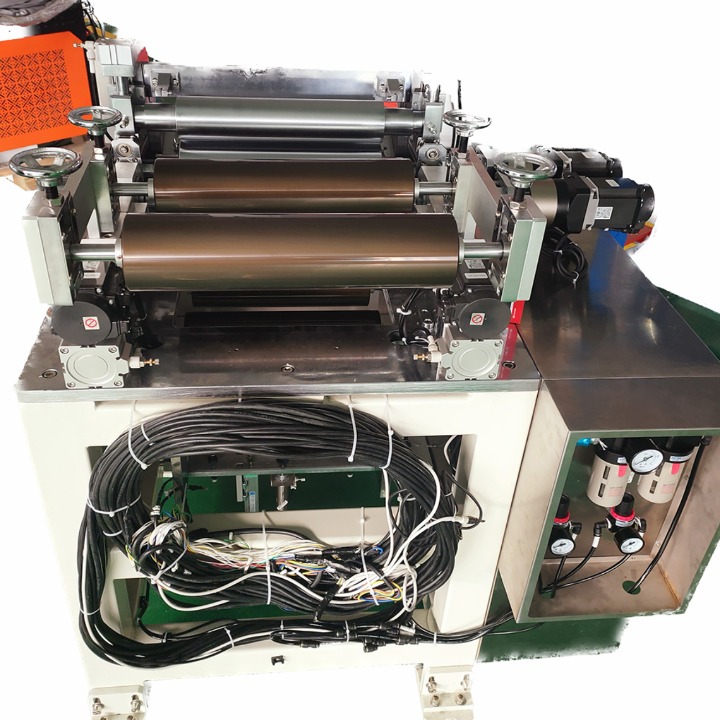

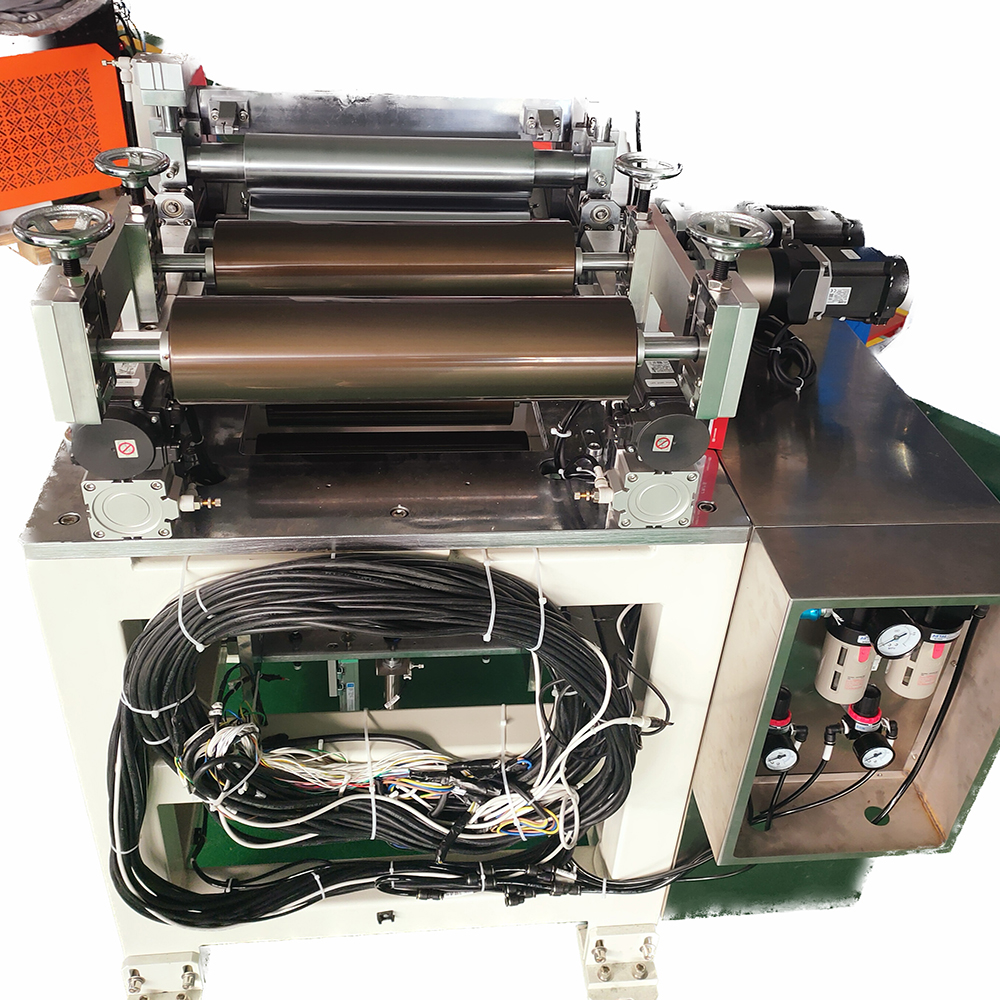

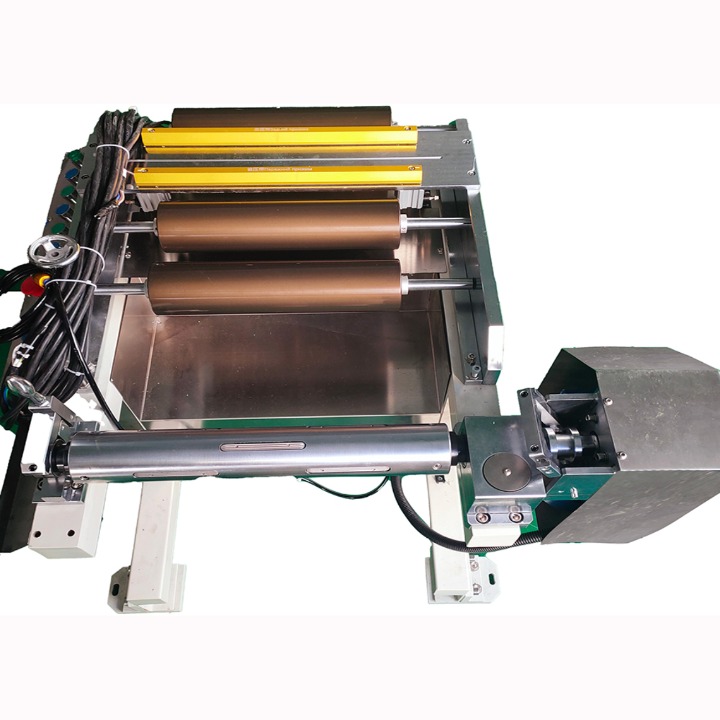

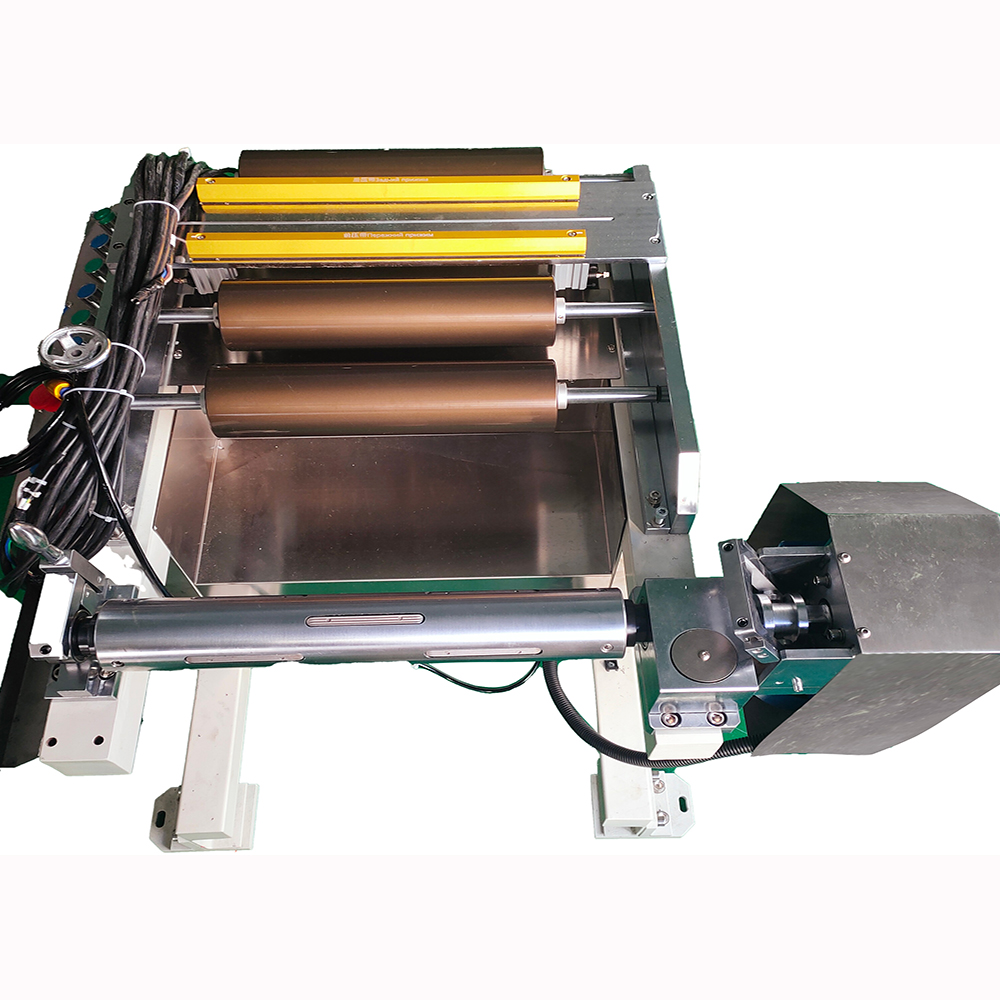

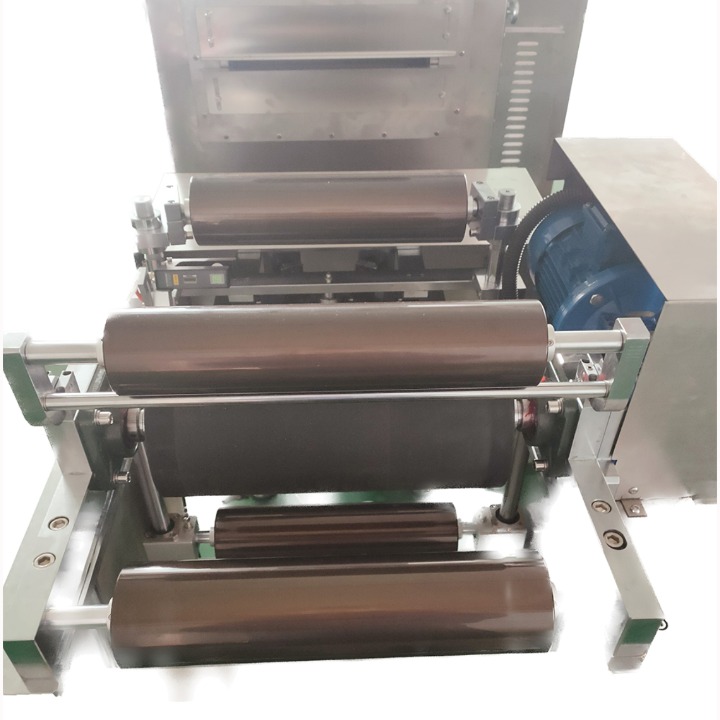

Introduction of equipment function and principle: High-precision clearance transfer comachine is mainly composed of roll mechanism, correction mechanism, tension control, coating mechanism, drying mechanism, traction mechanism and winding mechanism; evenly coat the stirred polar paste film on the substrate to ensure the size and weight in the design specification range, harvest film roll after drying treatment, and make preliminary preparation for the later process.

2. Equipment characteristics

- Various choices of coating mode: continuous coating, one gap coating, two gap coating, three gap coating, reverse overlapping coating, reverse dislocation coating.

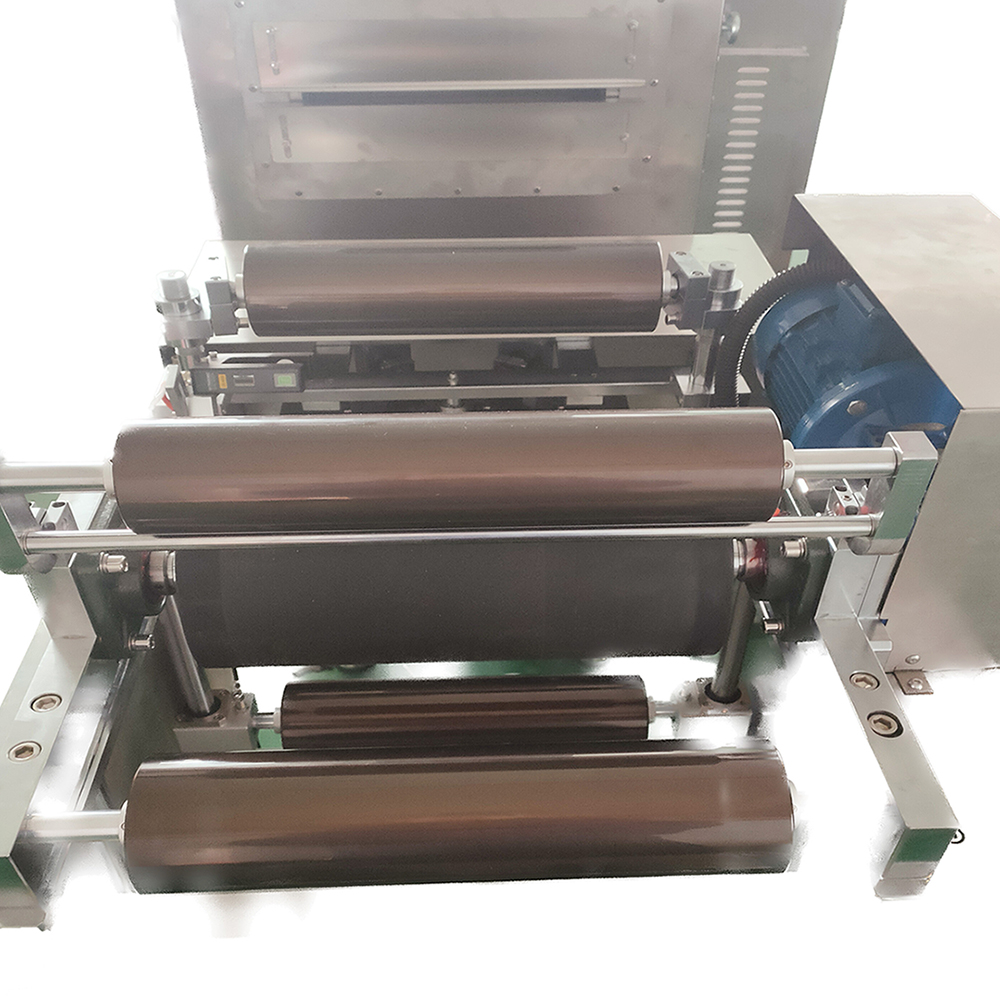

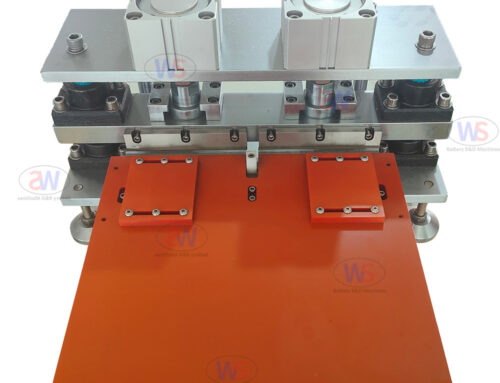

- Precision adjustment of the scraper mechanism: the high-precision servo motor is mobile lift scraper, and the lifting adjustment accuracy is 0.001mm, a total of 2 sets.

- Precision adjustment of the rubber roller moving mechanism: the imported servo motor drives the high-precision wire rod to move the rubber roller, and the moving adjustment accuracy is 0.01mm, a total of 2 sets.

- Precision correction control of the whole process: roll correction, traction correction, collection and correction, a total of 4 sets.

- High precision constant frequency conversion tension control: constant tension in the rewinding area, constant tension in the traction area, constant tension in the rewinding area, constant tension, a total of 3 sets.

- Oven circulating air design, save loss: independent inverter adjustment of blower and exhaust fan in each area.

- All stainless steel structure, integral stainless steel box, stainless steel heating pipe, stainless steel fan, stainless steel rack, stainless steel sealing plate.

- Roller selected alumina roller, resistant to more than five years of wear, imported roller bearing.

- Powerful and perfect control system: dangerous operation protection, alarm prompt, fault maintenance help.

Specification of Equipment

| outline dimension: | Demand installation space |

| Four box body | Length 19000mm * width 1800 * height 2100 |

| 5 Box body | 22000mm length * 1800 width * 2100 height |

| Six box body | 2th 25000mm * 1800 * 2100 height |

| Configure the power supply | AC380V Five lines, three-phase main line using 16mm² or above, zero line 10mm², ground line 6mm², total power switch 100A. |

| Configure the compressed gas source | ≧0.7MPA,20L/min。 |

| plant capacity | 4-section ovens, with a starting power of 40KW, and an average operating power of 22KW / H (depending on the heating temperature).

For type selection and supplement, the starting power of each oven is 11KW (heating pipe 10KW, fan 0.75KW). |

| Range of normal operating substrate | 8um~50um |

| Effective coating width | 300mm, the length of roller and roller is 350mm |

| Normal single-surface coating thickness range | 35um~250um |

| Normal coating accuracy | Single-sided thickness ± 2um, double-sided thickness ± 3um; single-sided surface density ± 1%, and double-sided surface density ± 1.5% |

| Effective coating length range | The coating length is 20mm~9999mm; the gap length is 5mm~9999mm |

| Coating length accuracy | Coating length is 0.3mm, gap length is 0.3mm, average length deviation is ± 0.3mm, tratail length is 0.5mm, coating width is ± 0.3mm, positive and negative alignment is ± 0.3mm. |

| Suitable for slurry | Lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, ternary and other system battery positive and negative electrode coating process |

| dissolvant | The NMP / aqueous group |

| Solid content: | 30-75 % |

| Suitable for slurry viscosity | Negative electrode from 1500 to 3500 Cps

Positive pole 6000 ~ 12000 Cps |

| running speed | Apply normal speed 1m / min~2m / min and mechanical speed 1m / min~15m / min |

| The drying temperature range | Room temperature ~160 degrees Celsius, temperature deviation ± 2 degrees Celsius, each area independently set up control |

| Collect and release the roll and correction accuracy | ≤±0.5mm |