Project Description

φ300mm×350mm

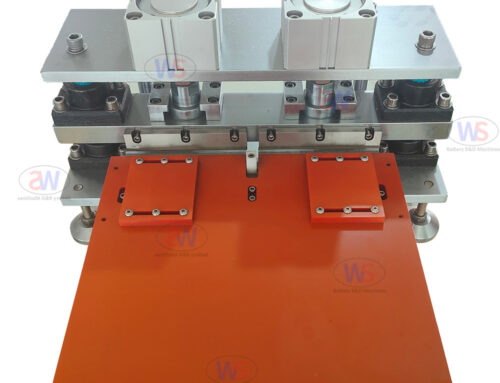

Cold Lam (Cold pressure)

Operation function:

Compaction the coated poles to achieve the proper density and thickness

- principle:

By adjusting the gap of the pressure roller to adjust the pressure, the thickness and density of the compaction at the pole are adjusted

Basic parameters of the equipment:

1) Roll size: φ300mm 350mm;

2) Compressed air: 0.5Mpa~0.7Mpa (oil, water), flow rate: 0.04M3 / min

3) Service environment: the temperature range is 0~ + 45℃ Relative humidity: 50%

4) Maximum rolling line speed: 8m / min;

5) Maximum working pressure: 60T;

6) Adapt to the size range of the battery or the pole sheet: the pole sheet width is not more than 330mm, and the thickness is 0.5-3mm;

7) The coil diameter is 400mm and the coil weight is 300kg

8) Overroll material: aluminum alloy, surface oxidation treatment HV 700

9) Power supply requirements: 380V / 50Hz, power of 5KW;

10) Equipment failure rate: 1% (excluding poor incoming material and plant power supply and gas supply influencing factors)

11) Qualified rate of production products: 99%

12) The host weight is about 2.2T

13) Total weight of the equipment: about 3T,

14) Ground bearing requirements for equipment installation:> 3T / m2, and place pads at the bottom of the equipment.

15) Spray color: the supplier’s standard color or specified color.

16) Size of roller press: about length 1650mm width 600mm height 1200mm

17) Size of the production line: about length, 4,360 mm, width, 1,650 mm, height, 1,200 mm (excluding the reserved space for roll removal).

Blade specification: Top knife Φ 100 * Φ 65 * 1mm (2 slices) Down Φ 100 * Φ 75 * 10mm (2 slices) Speed (max): 50r / min (adjustable)

Cutting edge width: 100 mm~330mm (continuous adjustable) Motor power: 200W (single phase 220V 50Hz)

φ400mm×450mm

- Device function:

- Composition of roller press: automatic roll unit, deviation correction unit, roller unit, traction unit, automatic winding unit, control system;

- Coiling material by manual feeding and underfeeding;

- Compatible with manual large roll and automatic roll continuous roll;

- Configuration of manual feeding and feeding operation platform;

- Roller press with automatic scraping roller device;

- Adopt the cold pressure mode;

- Main technical parameters of the equipment

- Compaction density: 4g / cm at the positive electrode3, Negative electrode: 1.8g / cm3

- Effective coating width: 350mm, total width of foil: 400mm

- Pressure of the main roller line: 10T / cm

- Roller thickness deviation: ± 2um

- Equipment performance indicators:

| 1. | Effect of wrinkle removal device: no cracks and fold, take 1m long pole slice and tile along 20mm from the coating edge, and measure the wave edge of 1mm |

| 2. | Mechanical speed: 30m / min |

| 3. | Depdepth of main roller: 20mm |

| 4. | Thickness of chrome plating layer of main roller: 180um |

| 5. | Face hardness of main roller: HRC 66-68 |

| 6. | Hardness uniformity of the main roller surface: 2 HRC |

| 7. | Roughness of the main roll surface: Ra≤0.02um |

| 8. | Flintness of main roller surface: 1um5 |

| 9. | Cylindricity of the main roller: 1um |

| 10. | Radial beating of main roller installation: 1um |

| 11. | Installation accuracy of guide roller: parallel ± 0.05mm, level ± 0.02mm |

| 12. | Radial run-out of the guide roll: 20um |

| 13. | Volume alignment: ± 0.2mm, production speed: 20m / min |

φ500mm×550mm。

The roller machine is the main equipment in the continuous rolling production line, which is composed of rigid frame, roll, universal coupling, motor reducer, air-liquid pressurization system, gap adjustment system, electrical control system, feeding guard plate and roller surface cleaning mechanism.

The main function is to make the pole sheet under the roll rolling, so that the pole sheet reaches the appropriate compactness, and to reach the pole sheet thickness requirements according to the coating thickness. This equipment adopts the ball-wire rod and wedge-iron clearance adjustment structure to adjust the roll clearance, and the linear speed is adjusted through the frequency converter.

Main technical parameters:

- Roll size: φ 500mm 550mm;

- Rolling line speed: 2~12m / min

- Maximum working pressure: 500 KN-6000 KN;

- Power supply requirements: 380V / 50Hz, power of 10KW;

- Compressed air: pressure: 0.5Mpa~0.7Mpa, flow rate: 0.04M3/min ;

- Total weight of the equipment: about 10T,

Ground load-bearing requirements for equipment installation:> 2.8T / m2, And place the pads at the bottom of the device.

- Spray color: Supplier standard color or specified color.

- Equipment size: the length of the roller machine part about 3100mm width 1000mm height 2000mm height

The overall size of the equipment is about 6000mm wide 3100mm high 2000mm.