Project Description

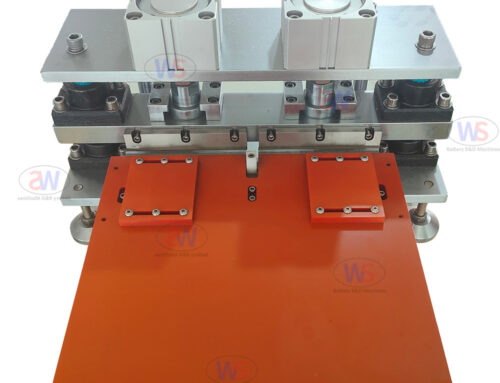

Punching Machine

Suitable for flexible packaging lithium battery cell aluminum plastic film single piece manual operation stamping molding

The gas-liquid booster cylinder provides high output safety light curtain protection

Applicable die: two-sheet die / spring die

characteristic:

- Plate aluminum plastic film molding, suitable for research and development and sample preparation;

- Gas-liquid pressurization cylinder and servo motor drive, punching depth, molding pressure and speed can be programmed;

- High strength frame, upper and lower precision template, to ensure the molding accuracy;

- The forming product stretching evenly, high quality stretching effect, no strain, rupture and other bad;

- Mold specifications can be customized according to customer requirements;

- The number of aluminum-plastic film punching pit can be automatically counted;

- Design of security grating, access control, scapegoat, scapegoat detection sensors, to ensure the safety of operators;

- Equipped with the mold replacement lifting trolley, the loading and unloading mold is convenient and safe;

- PLC control, HMI operation, convenient and easy to use.

| technical parameter | |

| source | Single-phase AC220V± 10% (customizable AC110V), frequency of 50Hz / 60Hz, and power of 1.5KW |

| air supply | 0.5-0.8MPa Compressed air |

| opening stroke | 90mm |

| The depth of the pit | Min.0.5mm, Max.6mm, related to the aluminum-plastic film material and thickness |

| Forming accuracy | ±0.05mm |

| Equipment size | L1100*W840*H2100mm |

| weight | About 1,800 Kg |