Project Description

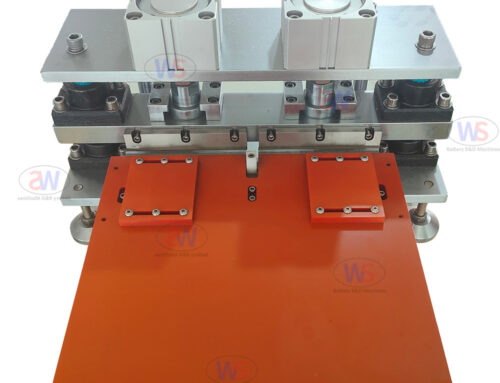

Liquid Injection Machine

Ingect (injection) – -basically the same as lamination

- Process function: add the electrolyte to the cell, and seal the cell completely

- Environmental requirements: water should be removed before cell injection, and the process requires low humidity

- Principle: Water, as a trace component in the electrolyte, has a great impact on the formation of SEI film and battery performance of lithium ion battery. The negative electrode in the full charge state has similar properties with lithium metal, and can directly react with water. Therefore, in the production process of lithium ion battery, the water content of the cathode material and the electrolyte must be strictly controlled and the humidity of the environment.

WC-100g

- technical parameter:

Main performance specifications of the equipment: the equipment external dimensions: 760mm (L) X440mm (W) X840mm (H), the quality of about 65 KG

- Power supply configuration: AC220V / 50Hz power: 2 Kw

- The product qualified rate is 99%

- Equipment failure rate of 1%

- Equipment running rate: 98%

- Vacuum degree of liquid injection: -97 Kpa

- Device function:

Using manual liquid injection, the equipment is equipped with a liquid injection pump. The equipment shall not be equipped with an electrolyte storage device, and the electrolyte storage shall be provided by Party A; with the function of fluid injection volume and fluid injection speed adjustment; the fluid injection and weighing shall be equipped with a cell placement clamp.