Project Description

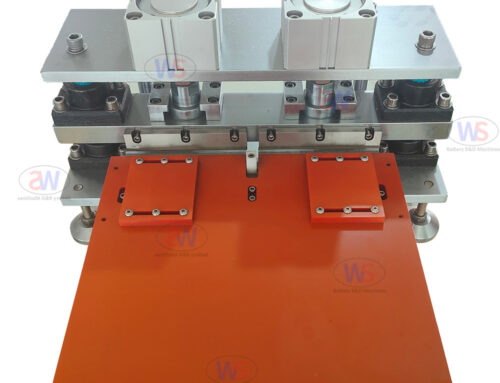

Semi-automatic Stacking Machine

Stacking (Disc)

Operation function:

The positive and negative electrode sheets, isolation film, and negative electrode sheets are regularly overlapped by hand or fixture.

- Equipment function

This machine is mainly used for the lamination of square lithium-ion power battery cells. The working process is as follows: actively roll the diaphragm, through the ferry and tension mechanism, introduce the stack table; the suction cup manipulator moves left and right to drive the diaphragm into Z-shaped movement; the left and right suction cups remove the positive and negative electrode pieces from the two material boxes, and then alternately stacked on the stack table; After the stack, the feeder manipulator takes the core.

Machine performance parameters

- The overall alignment accuracy of the diaphragm is ±3 mm;

- The overall alignment accuracy of the pole sheet is ±3 mm;

- The alignment accuracy of adjacent poles is ±3 mm;

- Production beat: lamination time (1.3-1.5 seconds / number of layers) + ending time (15 seconds);

- Qualified rate: 98% (except for poor incoming materials and misoperation);

- Operating rate: 95% (except for failure within 10 minutes);

- Overall dimensions: 1300 mm (L) 1000mm (W) 2100mm (H) (subject to the final design);

- Power supply: 220VAC ± 5, single-phase, 10 KW;

- Gas source: 0.5~0.6 Kgf / cm², 100 l / min;

- Vacuum source: -0.09MPa, 100 l / min;

- Non-corrosive gas, liquid, and explosive gas;

- Weight: 1500 Kg (bearing ground bearing not less than 500 Kg / m2).

functional characteristics:

- The diaphragm release mechanism is set up with the deviation correction device, using the floating roller to control the diaphragm tension;

- The pole piece handling mechanism is driven by a servo motor with precise positioning;

- There are positive and negative pole plate positioning devices, and the pole plate is positioned by the mechanical secondary positioning mechanism;

- The stack table is set with a precision guidance mechanism to make the laminated table rise and fall in real time according to the laminated thickness;

- The positive and negative electrode pads are designed separately to avoid the mixing of positive and negative materials;

- Take the unloading cell to the unloading station, and collect the cell by manual;

- The equipment has friendly interface, easy to operate, simple maintenance, stable and reliable operation; the top of the equipment has indicator (red: fault green: running yellow: standby); the equipment has maintenance count and prompt function.