Project Description

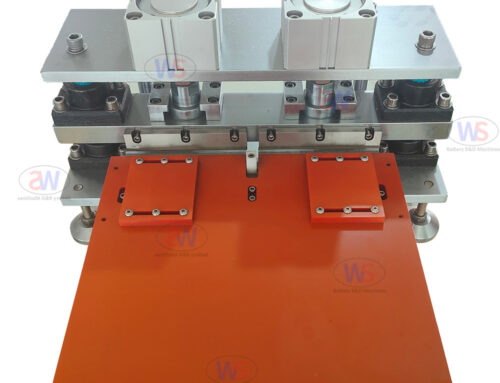

Ultrasonic Spot Welding Machine

Welding (Welding)

Process function: weld multiple AI and Ni pole ears together into bare cells

Principle: Ultrasonic welding uses the mechanical vibration energy of ultrasonic frequency (more than 16 KHZ) under the joint action of static pressure to transform the elastic vibration energy between the friction work, deformation energy and the subsequent limited temperature rise, so as to achieve the purpose of connecting heterogeneous metals.

JHN2060 Performance features

A, using advanced constant current constant voltage circuit technology, ultrasonic amplitude continuous adjustable;

- Adopt intelligent ICS case control system, with secondary ultrasonic function; The system boot self-inspection, vibration auxiliary intelligent segmentation, automatic tracking, provide the machine signal transmission function.

- The mechanical structure of the nose adopts the German-type X guide rail structure, with extremely high precision;

Equipment performance indicators

Ultrasound frequency: 20 KHz

Ultrasonic power: 3000-6000W

Air pressure: 0.2-0.8MPA

Welding time: within 1S

Voltage: 380V / 50Hz

Weight: 60 KG

Length of solder joint: 20mm / 35mm

Welding joint width: 3mm

Height of the solder joint: 1mm