Project Description

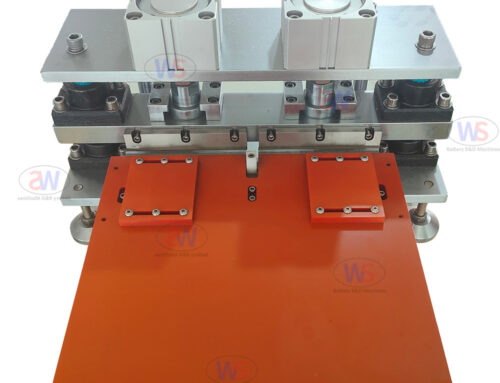

Vacuum Static Box

- The machine is suitable for drying room, especially the glove box for vacuum state, the electrolyte quickly and evenly permeate into the cell

- Appearance dimensions: 730 * 480 * 1130MM

- Equipment weight: 87 KG

- Internal cavity specification: 550 * 450 * 500

- The cylinder drives the cavity up and down, convenient feeding, with a wait and see window, observe the cell at any time

- PLC automatic control, standing time and number of times gram arbitrary set

- Perfect security protection function: safe light screen setting

1.Overview:

It is suitable for vacuuming the battery after liquid injection, so that the gas in the battery can be extracted from the electrolyte, and the electrolyte can quickly and evenly penetrate into the battery pole piece. Put the battery bar into the cavity of the vacuum static machine for positioning, and perform vacuum pre-seal after the static is completed. The equipment is equipped with a cell static rack for putting into a vacuum box for static operation. The vacuum parameters and cycle times of the static box are adjustable. , Vacuum pre-sealing temperature, vacuum degree, pressure, packaging time, etc. are adjustable, with parameter setting and display functions.

2.Power configuration and installation parameters:

- Configured power supply: 220V / 50Hz; power: 0.5KW

- Compressed air: 0.6 Mpa, 5L / Min

- Vacuum source: -100 KPa, flow rate of 10L / Min

- Equipment weight: about 90 Kg

- Equipment size: main body: 630x350x700 mm

- Noise requirement: 75dB, 1m distance from the outer wall of the equipment

- product percent of pass: 99%

- equipment failure rate: 1% of the failure caused by the equipment

- Fault downtime: 30min / day, more than 30min fault once / month

- Equipment growth rate: ≥98%

- Equipment failure rate: 1%